Remote Data-Logging / Monitoring

WebProCat Data Center

Web-based Data Management System

For G-DART Remote Monitoring and Control Units

B&A Manufacturing Product

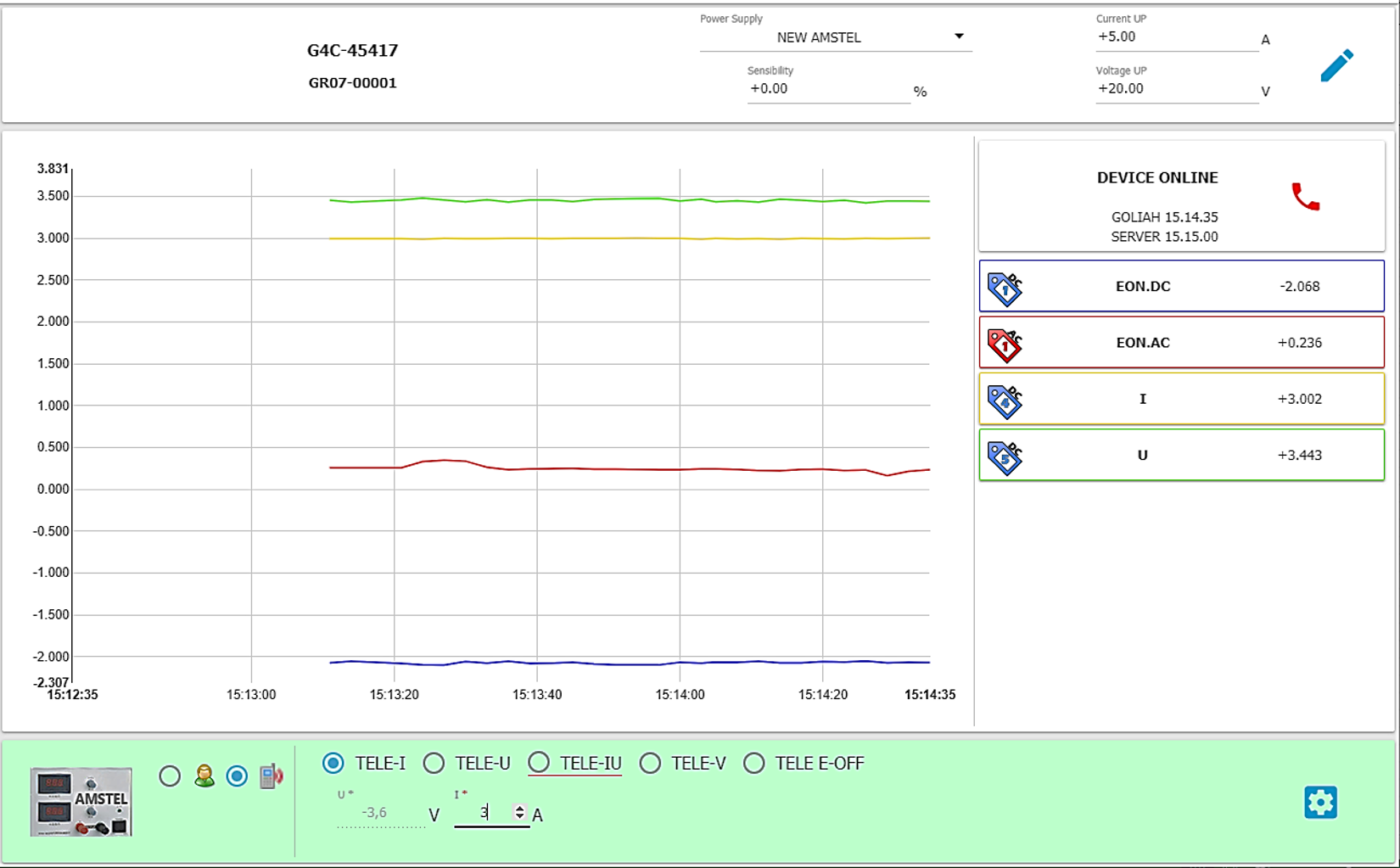

The WebProCat® Data Center software interface allows you to manage your whole Cathodic Protection system from one single screen. Imagine a map of your facility or pipeline system on your computer screen; now, you can retrieve the output of your rectifier and all your test stations by clicking on the icon of your field unit.

Access daily smart summary report with Maximum, Minimum Average, etc. values, historical data and alarms at the WebProCat® Data Center from your smartphone, tablet, laptop, or desktop. Compatible with existing Data Bases like Miller Proactive®, Bass Trigon®, MS Power BI®, etc.

The WebProCat® Data Center can access any of the G-DART® and DART® Remote Monitoring Units to automatically monitor and control digital/analog functions and processes associated with Cathodic Protection (CP) systems for the Energy and Critical Infrastructure industries.

-

The user interface is intuitive and easy to navigate at any user level.

It facilitates fast and accurate analysis of data to diagnose problems and identify solutions.

WebProCat® Data Center features interactive maps giving you clickable RMU locations.

Synchronized interruption of rectifiers by a GPS receiver.

Multiple variables are graphed simultaneously for analysis.

You can generate and export reports and graphics into virtually any format or software like Excel, PDF, JPEG, etc.

Instant off potential readings presented in graphics for easy analysis.

Monitor Corrosion Rate from ER probes.

Live Monitoring and Control of Automatic Rectifiers.

Design your own Dashboard for a fast overview of your CP system.

Complete real time alarm system with text message and e-mail capabilities.

Access your Cathodic Protection system from any authorized computer within the network.

-

Our sophisticated encryption system protects the data transmissions to ensure that the information is safe.

You can always access historical data for diagnosis and analysis.

Customizable password-protected user levels.

Unlimited Data-logging capacity.

Information is transmitted from the field to a data center and vice versa through ANY communication system available: GSM cellular network, radio, satellite, fiber optic, microwave, SCADA, MODBUS, et cetera.

Compliant with current industry regulations.

Synchronizes field measurement or maintenance entries with FIDO Universal Bluetooth App

-

Monitoring:

All CP system readings and functions

AC and DC voltages and currents

Instant OFF-potential readings

100 millivolt shifts

AC and DC Current density

Ratio of DC Potential vs. AC Current Density

Corrosion Rate from ER Probes

Alarms from analog or digital signals

Control:

GPS cyclic interruption

On-Off switch

Rectifier Output

Constant Voltage

Constant Current

Constant Potential

-

G-DART® for Test Stations

G-DART® for Rectifiers

STREET DART® for Underground Test Stations

FIDO® Universal Bluetooth App

-

Monitoring systems at sites affected by distant location, difficult access, or vandalism

Periodic and historical reports

Data analysis

Preventive maintenance and alarm notifications

Database management and information integrity

Large infrastructure projects

Subways with drainage bond systems for DC electric railway

High-frequency data logging

Compliance with ALL regulatory requirements

BORIN® offers extensive field support for installation and commissioning.